Case Study 1

A Better PET Jar Design

With a More Sustainable Footprint

Goal: Reduce the cost of an existing PET jar design while retaining product capacity and footprint.

What

We Did

To achieve our client’s objective of lowering overall costs, our custom PET bottle designers reduced jar weight by 25%. By using a unique ribbed design, we were able to maintain the required structural integrity in this lighter-weight jar.

The

Results

Not only was our client able to obtain cost savings with a lighter PET jar design, we also helped them reduce their overall carbon footprint.

The

Results

Not only was our client able to obtain cost savings with a lighter PET jar design, we also helped them reduce their overall carbon footprint.

Case Study 2

Speeding a New PET

Jar Design to Market

A client needed a new PET jar design on store shelves within 90 days. Most club stores specify acceptable jar dimensions, so our task was to customize our blow molding within these restrictions while introducing a new and unique jar.

What

We Did

Our design team worked swiftly to create a unique PET jar design using hexagonal elements to differentiate from other packages on the market while satisfying the dimensional requirements.

The

Results

With our expertise for custom plastic packaging design and production, we delivered shelf-ready jars in just 90 days, achieving the client's time-to-market goal while also delivering a unique PET jar design that clearly differentiated their product.

The

Results

With our expertise for custom plastic packaging design and production, we delivered shelf-ready jars in just 90 days, achieving the client's time-to-market goal while also delivering a unique PET jar design that clearly differentiated their product.

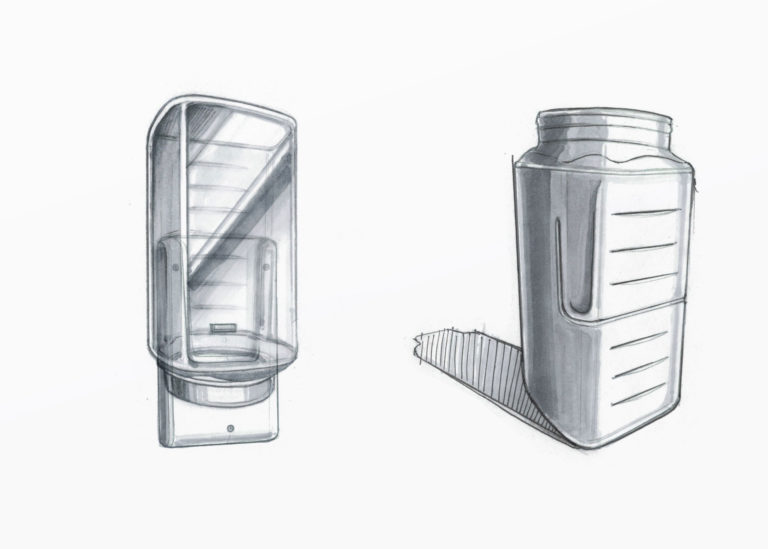

Case Study 3

Showcasing Our

Production Expertise

The customer’s two-piece design proved virtually impossible to make and used an expensive and difficult-to-source resin. Faced with these issues, they turned to VPET to develop a more viable jar design in PET, using our two-stage custom blow molding process.

What

We Did

Not only did we help our client source a less expensive resin with a consistent supply; our PET jar designers improved the client’s original sketches to make the two-in-one jar solution blow-friendly using our unique two-stage stretch blow molding process

The

Results

We helped our client introduce a new shape that is multifunctional, less costly, and unique to them. With the new PET jar design, our client enjoyed lower operational costs and overall cost savings while reinforcing their own unique brand presence.

The

Results

We helped our client introduce a new shape that is multifunctional, less costly, and unique to them. With the new PET jar design, our client enjoyed lower operational costs and overall cost savings while reinforcing their own unique brand presence.